HOME > Resources > Technical Center > Material Selection

Material Selection

In our first article, we introduced the key elements in successful pipe system design – material selection, component design, support design, system stress analysis, and installation. In this article we are going to take a closer look at the first of these elements, i.e. material selection.

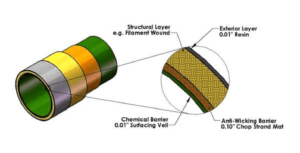

Composite piping systems are manufactured with a corrosion barrier and a structural laminate. The corrosion barrier provides the chemical resistance needed to protect the structural laminate so that the piping system can perform its intended function. There is a wide range of corrosion barriers commonly used in the Corrosion Industry, everything from just a surfacing veil in a light duty resin system, to corrosion barriers containing multiple layers of surfacing veil and chopped strand mat manufactured using premium grade resins, to those made using fluoropolymer materials. For long term, trouble-free service of your piping system, you need to have a corrosion barrier that will stand up to the challenge of your application. But there can be significant cost differences between the various corrosion barrier configurations. Choosing the right configuration for the application will ensure you get the performance you want without paying for more than you need.

The first step in selecting the right corrosion barrier configuration is accurately defining the environment to which the piping will be exposed. Items that need to be identified are:

- Chemical environment

- Concentrations of chemicals (normal and maximum)

- Process temperatures (normal operating and upset)

It’s important to consider not only the individual chemicals that will be present in the process stream, but also the combinations of chemicals that might be present. The particular combination of chemicals could pose additional corrosion challenges that need to be addressed. It’s also very important to accurately define the temperatures of the process stream as chemical attack can be significantly accelerated at higher temperatures.

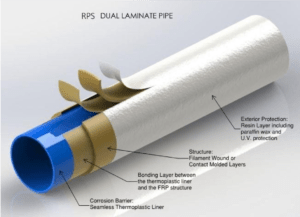

With the process conditions properly defined, we can determine whether an FRP corrosion barrier will be suitable for the conditions, or whether it will be necessary to use a thermoplastic corrosion barrier, i.e., a dual laminate piping system.

For most corrosion applications, the standard FRP corrosion barrier is 0.100” – 0.120” (2.5 – 3.0 mm) thick, consisting of 1 or 2 layers of surfacing veil and 2 layers of chopped strand mat. Surfacing veils are usually composed of “C” glass or polyester; both are commonly used and both are resistant to a wide range of process conditions. There are a few applications where one would be preferred over the other such as hydrochloric acid where “C” veil would be preferred, or hydrofluoric acid where polyester would be preferred, but both types of veil have been used successfully in many applications.

Chopped strand mat is either “E” or “ECR” glass. “E” glass has been used successfully in corrosion barriers for over fifty years. “ECR” glass, which is a boron-free form of “E” glass, has been gaining wide acceptance in recent years. “ECR” glass displays improved chemical resistance in some services (particularly acids), and it also displays moderately better mechanical properties. While the “110 mil” corrosion barrier is the most widely used configuration, thicker corrosion barriers, e.g. 0.22” (5.6 mm) are often specified for more aggressive services.

At least as important as the thickness of corrosion barrier is the choice of resin. There are resins available in the Industry such as Isophthalic and Terephthalic polyester resins that will provide good chemical resistance to many dilute chemicals at moderate temperatures. But for most corrosion applications, it is necessary to choose higher grades of resins. There are specialty resins available that are particularly well suited to specific applications such as the bis-A fumarate polyesters in alkaline environments, but the workhorses in the industry today are the vinylester resins (VE resins). The bisphenol epoxy VE resin is the most commonly used VE resin and it is suitable for a very wide range of chemical services in temperatures up to approximately 200°F (93°C). For higher temperatures, VE resins based on novolac epoxy can be used. These resins are more expensive, but they can provide much better chemical resistance and mechanical properties retention at elevated temperatures.

RPS has developed a number of FRP piping systems, which have been designed to provide outstanding chemical resistance to a wide range of chemical environments. The RPS family of High Performance Pre-Engineered (HPPE) FRP piping systems includes HPPE P-150, HPPE-A150, HPPE H-150, and HPPE H-150-200. HPPE P-150 and HPPE A-150 piping systems include a 0.11” (2.8 mm) corrosion barrier and are manufactured using bisphenol epoxy VE resins. The resin system in HPPE A-150 piping has been specially formulated to provide enhanced erosion resistance for use in slurry services. RPS HPPE H-150 and H-150-200 are manufactured using epoxy novolac VE resins and are suitable for higher temperature applications. HPPE H-150 includes the same 0.11” (2.8 mm) corrosion barrier as in HPPE P-150, while HPPE H-150-200 includes a 0.22” corrosion barrier for enhanced chemical resistance. However, if none of these HPPE FRP piping systems meets your specific needs, we would be happy to recommend and supply a custom FRP piping system that will.

For the particularly aggressive environments such as concentrated acids or alkalines at elevated temperatures, the best choice for chemical resistance is dual laminate piping, i.e. a composite piping system with a thermoplastic corrosion barrier and an FRP structural laminate. Our HPPE MAXAR™ piping for example is manufactured with fluropolymer linings of FEP, PFA, and PVDF. These corrosion barriers provide the very best chemical resistance available in composite piping systems.

RPS also offers other options in dual laminate piping systems that can provide more cost effective solutions for less aggressive services. These include corrosion barriers consisting of PVC, CPVC, PE, and PP. For more complete descriptions of our piping systems, please refer to our Pipe Selection Guide and to our individual Product Bulletins. To help you choose the right piping system for your particular application, please refer to the RPS Chemical Resistance Guide.

RPS has been supplying corrosion-resistant piping systems for well over forty years. With our extensive experience and our regular consultation with raw materials suppliers, we can offer assistance in selecting the best material for your application. And by offering a wide range of products, we can provide you with the best choice of piping system for that application. Please contact us; we would be happy to help you select the right composite piping material to meet your needs.

In our next article, we’ll begin our discussion on pressure design of piping components.

Previous in the series: Successful Pipe System Design

Next in the series: Pressure Design of FRP Piping Components