HOME > Industries > Additional

HIGH PURITY

RPS dual laminate fluoropolymers, like MAXAR™ Red Seamless PVDF/FRP, are ideal for high purity environments in the semiconductor, pharmaceutical, and biotechnology industries. Our PVDF has gained FDA compliances, can be steamed and ozone cleaned, is resistant to microbial growth, and above all, limits the impurities that could be leached into acids and other solutions.TOP 3 SOLUTIONS GENERALLY USED IN THIS INDUSTRY

STEEL PICKLING AND GALVANIZING

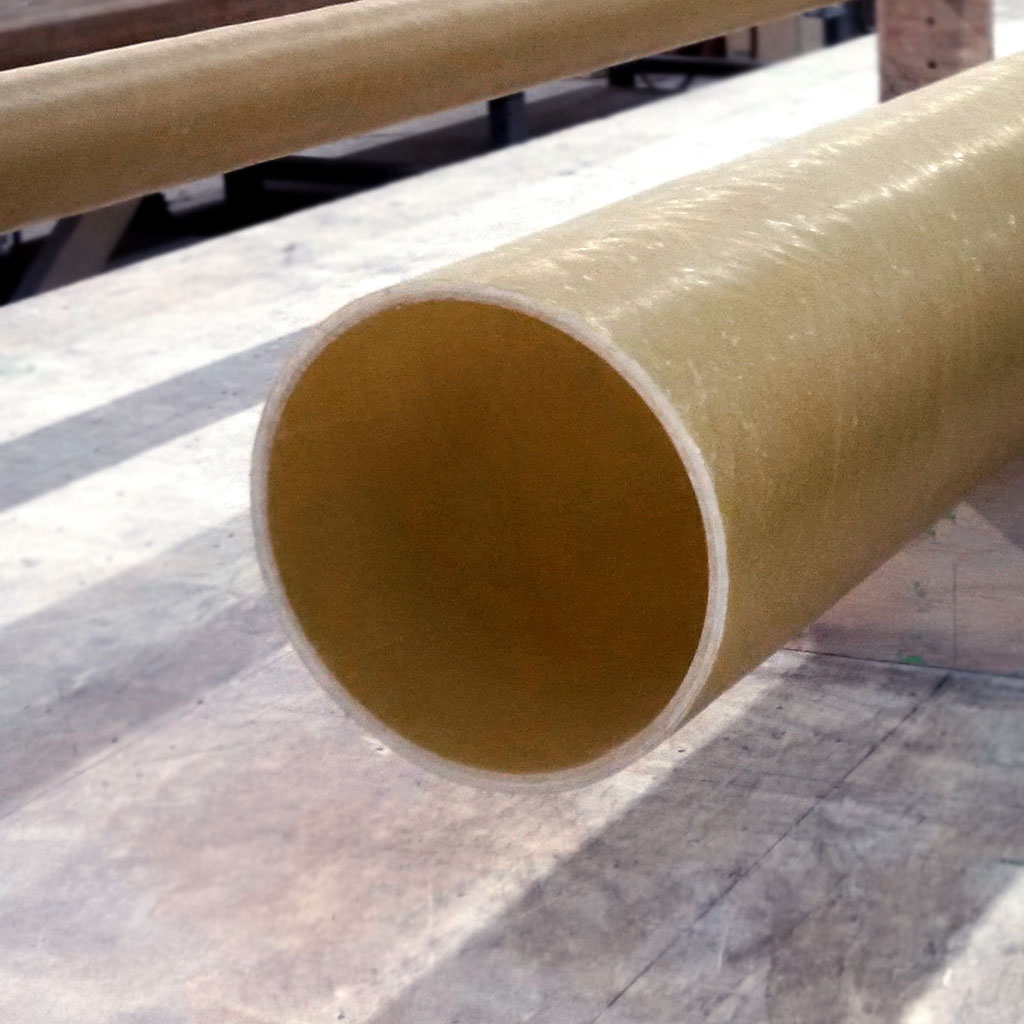

RPS Composites’ high-performance equipment excels in the corrosive atmosphere of a pickling line. This is a highly acidic environment that requires non-metallic vessels, piping, and venting equipment to contain acid, waste, and vapor. The hotter the process, the more likely that FRP will out-perform thermoplastics alone.

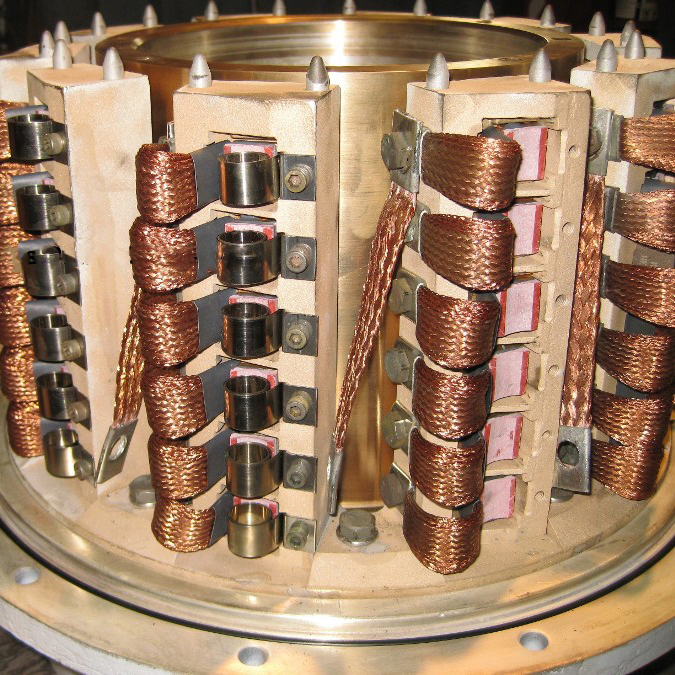

Electrogalvanizing is another highly corrosive environment due to the acid-zinc solution, and cleaning and rinsing baths, where non-metallic vessels, piping, and venting equipment are used. Most of our metals industry expertise is in our Ohio facility, where several key employees have direct experience in the steel industry.

TOP 3 SOLUTIONS GENERALLY USED IN THIS INDUSTRY

THE RPS

CHEMICAL RESISTANCE GUIDE

To assist with the selection and specification of FRP and Dual Laminate piping systems.

Case Study >

RPS Composites has worked in more than 45 countries around the world to provide customers with safe, timely, engineered composite solutions that provide decades of maintenance-free operation. Find out how we can help with your next project.