Pressure Design of FRP Piping Components – Flanges

HOME > Resources > Technical Center > Pressure Design of FRP Piping Components – Flanges

Pressure Design of FRP Piping Components – Flanges

In our previous articles, we looked at pressure design of piping components including pipe, fittings, and joints. In this article we are going to conclude our discussion on pressure design with a look at flanges.

Flanges present the greatest design challenge of all standard piping components. The theory underlying design of flanges is very complex, and the design methods are typically trial and error, i.e. a flange configuration is first assumed, and then it is checked for stresses. If the stresses are not acceptable, another configuration is assumed, and the stresses checked again. Flange design theories are generally complex for several reasons:

- A flange is not just a simple component like an elbow or a reducer; it is actually composed of several components acting together, i.e. the flange ring, the flange hub, the bolts, and the gasket.

- The individual components of the flange are typically composed of materials with significantly different properties. For example, the bolts are metallic and hence very stiff; the gasket is typically elastomeric and hence very flexible.

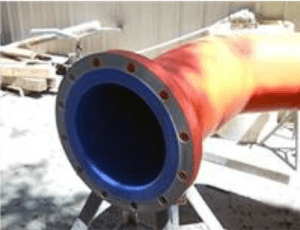

Figure 1: Contact molded, full-faced flange

As a result of these issues, most flange design approaches are either “simplified” elastic analyses, or even empirical in nature.

The most commonly used design methods for contact molded, full-face FRP pipe flanges (see Figure 1) are those found in ASME NM.21 ASME RTP-12 and ASME BPV Code Section X3. The methods are very similar, and for the same inputs, will yield virtually identical results. The methods are derived from the design method for metallic flanges found in the ASME BPV Code Section VIII4 for metallic pressure vessels. That design method applies to raised-face configurations where there is no contact between the flanges out beyond the bolt circle. Such a flange configuration results in high longitudinal hub stresses arising due to bolt tightening and operating loads, which would be difficult for a material like FRP to accommodate. For this reason, FRP flanges are most often designed with flange contact over the entire flange face. This configuration substantially reduces the longitudinal hub stresses. But given the greater contact area of the gasket, the initial bolt loads must be much higher to effectively seat the gaskets. To limit the bolt torques to reasonable levels requires the use of soft gaskets. Unfortunately, the soft gaskets limit the use of this configuration to relatively low pressures, e.g. 150 psi.

Adequacy of the design of contact molded flanges can be verified by demonstrating compliance to the performance requirements in ASTM D5421 “Contact Molded “Fiberglass” (Glass-Reinforced-Thermosetting Resin) Flanges”. These requirements include a sealing test, a bolt torque test, and a burst test. The flange must withstand a pressure of 1.5 times the pressure rating for 1 week without leakage; the flange must withstand a bolt torque of 2 times the recommended torque without visible signs of damage; and the flange must withstand a pressure of at least 4 times the rated pressure without failure.

Figure 2: Contact molded lap joint flange

There are instances where an FRP flange must be exposed to a raised-face configuration. These instances would include mating an FRP flange to a metallic pipe flange with a raised-face, or mating an FRP flange to a valve with a flat face but with a lining that covers the flange face only out to the bolt circle. Using a full face flange directly in these types of situations is not recommended due to the likelihood of over-stressing the flange during bolt-up or operation. If a full face FRP flange must be used, then a spacer ring should be inserted between the flange faces to fill the gap and hence eliminate the raised-face condition. An alternative solution would be to use an FRP Lap Joint flange in lieu of the full face flange (see Figure 2). An FRP Lap Joint flange has a stub OD that is the same diameter as the inside of the bolt circle. As long as the mating raised-face has the same OD, the bolt-up and operation stresses in the FRP Lap Joint flange will be much lower than they would be in a full face flange.

Design of contact molded Lap Joint flanges follows essentially the same approach as for the full face flanges, but, with the contact between flanges being entirely within the bolt circle, the design method in ASME Section VIII is more applicable.

Figure 3: Filament wound, full face flange

The design methods discussed so far are appropriate for contact molded flanges. But FRP flanges are often manufactured by methods other than contact molding. One such method is filament winding (see Figure 3). In this manufacturing method, the flange mold is rotated about the flange axis, and continuous strands of glass are applied in the hoop direction. This type of construction results in very high hoop strength and stiffness of the flange. Although the longitudinal strength of this type of laminate is relatively low, the stiffness provided by the hoop reinforcements and flange ring geometry, along with the greater thickness of these flanges often results in the filament wound flanges being capable of withstanding higher bolt-tightening loads and operation loads than contact molded flanges.

Due to the non-standard geometry of the flange and to the highly orthotropic properties of the laminate, standard design methods have not yet been developed. These flanges are typically designed by empirical methods, i.e. configurations that have been proven to work are modified as required to satisfy the design conditions. Filament wound flanges should be verified to comply with the performance requirements in ASTM D4024 “Machine Made “Fiberglass” (Glass-Reinforced-Thermosetting Resin) Flanges”. Like ASTM D5421, the performance criteria of ASTM D4024 include a sealing test, a bolt torque test, and a burst test.

This concludes our look at pressure design of piping components. In our next article, we’ll begin our look at piping system design and analysis.

1 ASME NM.2-2018 “Glass-Fiber-Reinforced Thermosetting-Resin Piping Systems”

2 ASME RTP-1 “Reinforced Thermoset Plastic Corrosion-Resistant Equipment”

3 ASME BPV Code Section X “Fiber-Reinforced Plastic Pressure Vessels”

4 ASME BPV Code Section VIII “Pressure Vessels”, Division 1, Appendix 2

Previous article in the series: Pressure Design of FRP Piping Components – Fittings and Joints

Next in the series: FRP Piping System Design